The pixel pitch of LED display is getting smaller than ever before. High pixel density require a high power consumption and produce a lot of heat. Traditional energy saving wont that help for the fine pitch LED display. Heat will cause color shift and moreover shorten the life time of LED diodes.

HXTECH engineer design a new solution which is called common cathode solution. We redesign our PCB layout based on the newest driving IC.

The LED chipset has two terminals, an anode and a cathode, and each full color LEDs consists of three LED chipset. (red, green and blue).

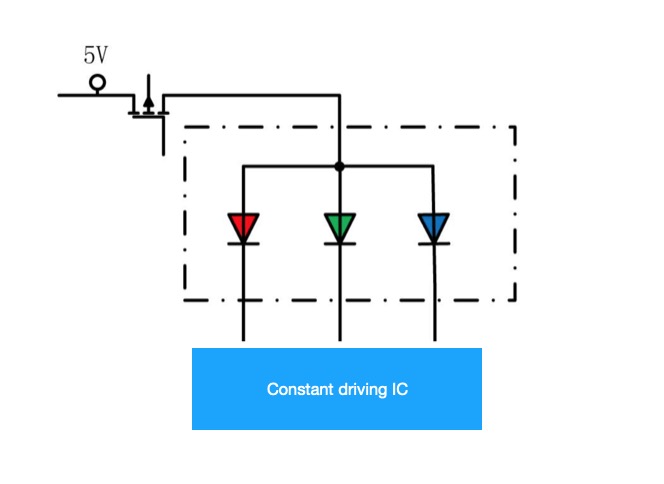

In traditional Common Anode designs, the terminals of all 3 (red, green & blue) LEDs are wired together and an external ballast resistor is added in series with the red LED to maintain a constant voltage and equalize the voltage drop across all three LEDs. This subsequently reduces available space for the LEDs making fine pixel pitch harder to achieve, while it is also an additional heat source and accelerates the aging process and reduces the lifetime.

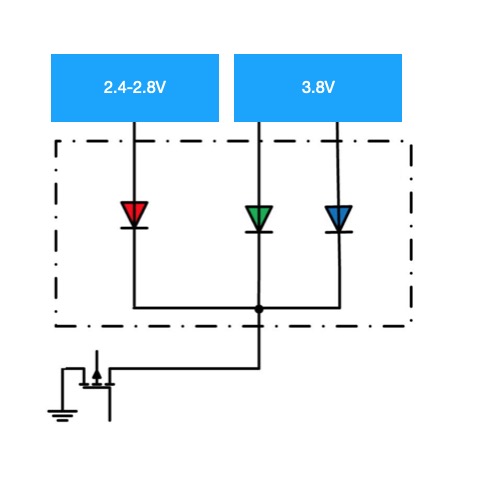

In Common Cathode technology, separate, dedicated power supply voltages are supplied to the red, green and blue LEDs enabling the power supplied to the red LED to be controlled separately and eliminating the requirement for a ballast resistor.

The traditional common anode driving method:

The common cathode diving method:

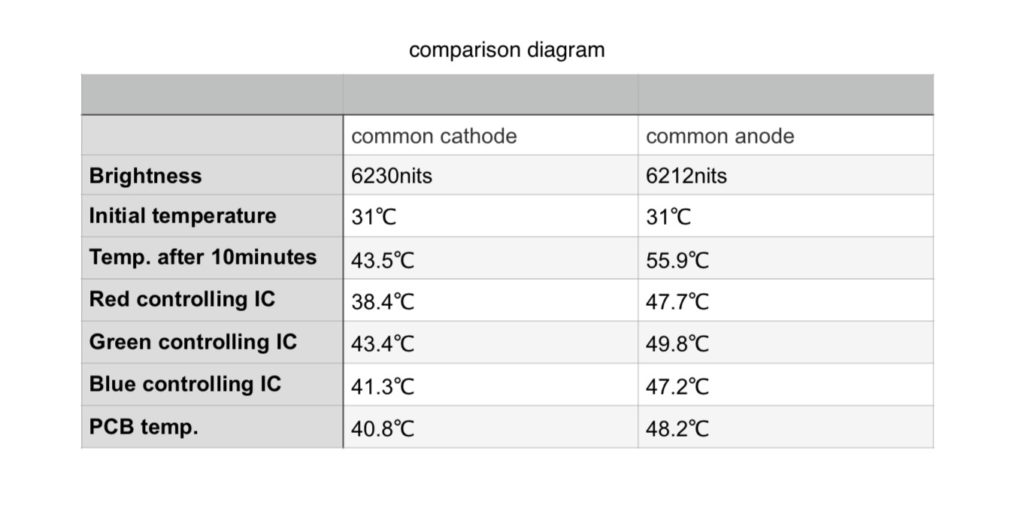

Following is a comparison diagram of surface temperature between common cathode design and common Anode design

The LED display surface temperature reduced 12.4 degree.In this case it can help a lot for a color uniformity and a long LED life time.

Our current product which is using common cathode design:

토토안전놀이터 인터넷바둑이하는곳 바카라 10연승시 50% 추가지급

해외안전놀이터 로우바둑이하는곳 블랙젝 3연승시 50% 추가지급

안전놀이터모음 실전바카라하는곳 ASIA CASINO 방문해주셔서 감사합니다.

해외안전놀이터추천 바둑이게임방법하는곳 먹튀없는 안전한 해외 카지노

My brother suggested I might like this web site.

He was entirely right. This post truly made my day. You can not imagine simply how much time I had spent for this

information! Thanks!

Awsome blog! I am loving it!! Will come back again. I am bookmarking your feeds also.